From Extraction to Final Product: Following the Artisanal Gold Production Network in the Eastern DR Congo

Words: Ben Radley

Photographs: Robert Carrubba

Français au-dessous d’anglais.

In the Democratic Republic of the Congo tens of thousands of rural families have experienced a long-term decline in their on-farm subsistence capacity due to government policy, war and demographic pressures. After agriculture, artisanal mining is now the second most important livelihood in the eastern DRC despite the inherent dangers of the work.

Between 2013 and 2015, the International Peace Information Service (IPIS) visited 1,615 artisanal mines across the region, recording the presence of 239,700 miners. Around 80 percent of these miners were working in gold mines, and around two-thirds were working in mines affected by the presence of the national army or a non-state armed group. Often, armed groups levy a tax or demand tribute in return for ‘protection’.

While much attention has been paid in recent years to the links between artisanal mining and conflict in the eastern DRC, less is known about the labour and production process itself. This photo story documents the process, following Congolese gold from its extraction at a rural artisanal gold mine in South Kivu Province, through processing and trade, to its transformation into a final product in the provincial capital, Bukavu.

Fr:

Après l’agriculture, l’exploitation minière artisanale est le principal moyen de subsistance dans l’Est de la République démocratique du Congo (RDC). En raison de la politique du gouvernement, de la guerre et des pressions démographiques, des dizaines de milliers de familles rurales congolaises ont connu un déclin à long terme de leurs capacités de subsistance à la ferme. Malgré les dangers inhérents au travail, l’exploitation minière artisanale a constitué pour ces familles une source importante d’emplois et de revenus, en dehors de la ferme.

Entre 2013 et 2015, le Service international d’information sur la paix (IPIS) a visité 1615 mines artisanales de la région, enregistrant la présence de 239.700 mineurs. Environ 80% de ces mineurs travaillaient dans des mines d’or, et environ deux tiers travaillaient dans des mines contrôlées par l’armée nationale ou un groupe armé non étatique. Souvent, des groupes armés perçoivent un impôt ou un tribut en échange d’une «protection».

Bien que les liens entre l’exploitation minière artisanale et les conflits dans l’Est de la RDC aient fait l’objet de beaucoup d’attention ces dernières années, on en sait moins sur le processus de travail et de production lui-même. Ce reportage photographique documente ce processus, depuis l’extraction de l’or dans une mine artisanale rurale de la province du Sud-Kivu, en passant par la transformation et le commerce, jusqu’à sa transformation en un produit final dans la capitale de la province, Bukavu.

Fr:

Des travailleurs de puits, connus sous le nom des « creuseurs », se détendent à l’extérieur d’un puits. Les revenus des creuseurs varient énormément, mais sont généralement meilleurs que les alternatives rurales, surtout si l’on possède peu de terres. Les pauvres vivant dans en milieu rural de la RDC ont afflué dans les mines afin de subvenir à leurs besoins et à ceux de leurs familles. 15 juillet 2017

Fr:

Deux creuseurs se tiennent à l’entrée de la mine qu’ils travaillent. 13 juillet 2017

Fr:

Un puits de mine en construction. Les gérants de puits, souvent financés par un négociant en or, peuvent investir entre 5000 et 50.000 $ au cours de cette étape de la construction d’une mine. Cela peut prendre plusieurs semaines, voire des mois, avant que le premier or ne soit extrait. Les creuseurs appellent cette période « la souffrance ». Les deux creuseurs qui creusaient ce puits ont demandé à ne pas être photographiés. 13 juillet 2017

Fr:

Un technicien en construction et entretien de puits est assis devant son magasin de bois. Ce type de travailleurs est très recherché dans les mines. Ils sont un peu plus âgés que la plupart des creuseurs et beaucoup ont appris leur métier en travaillant pour des sociétés minières industrielles pendant l’ère Mobutu. 13 juillet 2017

Fr:

Un spécialiste des machines en route pour un nouveau jour dans les mines. La plupart des puits atteignent plus de 50 mètres sous terre. À cette profondeur, des machines à oxygène sont nécessaires pour faire circuler l’air. Les spécialistes louent les machines à oxygène aux gérants de puits pour environ 10 $ par jour et assurent l’entretien sur site en cas de panne des machines. 15 juillet 2017

Fr:

Un gestionnaire de puits connecte le tuyau d’alimentation en oxygène à sa machine à oxygène. En avril 2017, sur ce site, un creuseur de dix-neuf ans est mort d’asphyxie. Un deuil de trois jours a eu lieu, pendant lequel personne ne travaillait à la mine. 14 juillet 2017

Fr:

Les creuseurs racontent une blague à l’entrée d’un puits. La confiance est un élément clé si l’on veut créer une entreprise rentable. Dans cette mine, la plupart des creuseurs sont des membres de la famille proche ou élargie des gérants de puits. 13 juillet 2017

Fr:

Les creuseurs sont vus dans un puits avec leurs phares. Un tuyau d’oxygène inutilisé passe à plat dans le puits et offre un appui-coude relativement doux. Selon la taille du puits, peuvent y travailler de cinq à cent personnes. Chaque équipe est dirigée par un gérant de puits (généralement aussi le propriétaire), un directeur adjoint et un secrétaire. L’an dernier, les gérants de puits de cette mine ont enregistré des bénéfices d’environ 12.000 $. En 2016, le revenu national brut par habitant de la RDC s’élevait à 420 $. 12 juillet 2017

Fr:

Dans les profondeurs, un creuseur extrait du minerai d’or de la terre. Les creuseurs passent six à huit heures par jour dans les puits. Le travail est physiquement exigeant. 12 juillet 2017

Fr:

Au fond d’un puits, un creuseur utilise son phare à la main pour regarder à travers un trou entre le plafond d’un puits déjà étroit et les sacs de minerai qu’il traîne vers la surface, mais qui le bloquent maintenant. Dans certains puits, les tunnels sont particulièrement étroits et difficiles à franchir. Traîner le minerai à travers ces puits est une tâche ardue. Pendant la saison des pluies, les puits peuvent s’effondrer sous le poids de l’eau absorbée par la terre située au-dessus. 13 juillet 2017

Fr:

Un creuseur manœuvre par un étroit croisement de tunnel, pendant que son collègue attend son tour. Devant lui, sont des sacs de minerai qu’il a poussés à travers le puits en direction de l’entrée. 13 juillet 2017

Fr:

Un creuseur s’étire pour extraire un sac de minerai d’or dans un tunnel. Les sacs sont difficiles à déplacer et lourds, chacun pesant environ 30 kg. C’est l’une des raisons pour lesquelles beaucoup de creuseurs sont des jeunes. Les creuseurs plus âgés se plaignent souvent de problèmes de dos. 12 juillet 2017

Fr:

Un creuseur transporte des sacs de minerai à travers le puits. 12 juillet 2017

Fr:

Au plus profond du puits dans laquelle il travaille, un creuseur fait la grimace en se glissant autour d’une solive de bois éclatée, tout en se dirigeant vers l’entrée du puit, à environ 50 mètres plus haut. Même pendant la saison sèche, les effondrements d’arbres constituent un risque. Cette poutre de support s’est fragmentée entre notre entrée et sortie du puits. 12 juillet 2017

Fr:

Deux tuyaux à oxygène indiquent le trajet qui mène à la surface, où des poutres en bois, à être transformées en supports, sont éclairées par la lumière du soleil qui s’infiltre dans la mine. 12 juillet 2017

Fr:

Trois creuseurs en dehors de leurs puits. Selon le gérant de puit, certains creuseurs sont payés en sacs de minerai d’or, d’autres en espèces et parfois en une combinaison des deux. Ceux payés en sacs sont souvent obligés de vendre l’or qu’ils trouvent à leur gérant. 15 juillet 2017

Fr:

Un enfant attache un sac à l’entrée d’un puits. Les écoles ferment en juin et pendant les vacances, de nombreux enfants rejoignent leur famille en travaillant dans les mines. Ceci peut aider à payer leurs frais de scolarité et à subvenir aux besoins de la famille. 15 juillet 2017

Fr:

Un porteur de sacs charge sa cargaison. Connus sous le nom de « motards » (ou « taximen »), ces porteurs travaillent indépendamment des équipes de puits. Ils sont employés par les gérants de puits pour transporter les sacs de minerai d’or vers un site de traitement, qui peut être proche ou jusqu’à un kilomètre de distance. Les plus grands puits produisent environ 50 sacs par jour. 15 juillet 2017

Fr:

Un porteur de sacs transporte son chargement en aval de la mine pour le traitement. Les porteurs perçoivent 500 francs congolais par sac (environ 0,35$ aux taux de change actuels de l’Est du Congo) et peuvent gagner plusieurs dollars par jour. Ils comptent parmi les salariés les moins payés de la mine. Sur ce site, il s’agit souvent des gens qui ont immigré d’autres régions. 14 juillet 2017

Fr:

Un porteur de sacs est en train de descendre la colline, tandis que d’autres se rendent dans deux sites de traitement différents. En février 2017, les gérants de puits ont réduit le paiement par sac à 400 francs congolais. Les porteurs ont entamé une grève de trois jours, obligeant les gérants de puits à reculer. 13 juillet 2017

Fr:

Une femme transporte de l’eau en haut de la colline jusqu’à un site de traitement voisin. Les travailleuses les moins bien rémunérées de la mine sont ces femmes qui transportent des bidons d’eau de 20 litres vers les sites de traitement où le minerai d’or est tamisé. Elles gagnent 250 francs congolais par conteneur (environ 0,2$ aux taux de change actuels de l’Est du Congo). Ce sont souvent des divorcées ou des veuves qui ont perdu leurs terres et leurs avoirs à la suite du divorce ou du décès de leur mari. 13 juillet 2017

Fr:

Les femmes transportent de l’eau sur la colline en se tenant à leur canne à sucre, qu’elles grignotent pendant leur travail. En bas de la colline, se trouvent quelques restaurants, coiffeurs et marchands de la mine. Certains des creuseurs habitent aussi en permanence sur le site, rejoignant la famille le week-end ou une fois par mois. 14 juillet 2017

Fr:

Un réparateur de téléphones sert un client sur un rebord. La plupart des creuseurs peuvent acquérir un téléphone portable grâce à leurs revenus. La réparation et le chargement de téléphones sont donc en grande demande sur le site. 13 juillet 2017

Fr:

Les enfants regardent un film dans l’une des salles de cinéma sur place. Lorsqu’on s’approche de la mine, on entend des films résonner tandis que des propriétaires de salles de cinéma tentent d’inciter les gens à payer le droit d’entrée. Les films d’arts martiaux sont les plus populaires, suivis des films d’action hollywoodiens. 15 juillet 2017

Fr:

Un enfant vend des cacahuètes au cinéma. La plupart des jeunes enfants de la mine ont des activités secondaires, en vendant de la nourriture ou en travaillant dans des restaurants. En général, seulement les enfants plus âgés travaillent dans les puits. 15 juillet 2017

Fr:

Un homme fait frire de la farine pour faire des beignets. Avec seulement 100 francs congolais (environ 0,10$), les beignets sont l’un des en-cas les plus populaires sur le site de la mine. 15 juillet 2017

Fr:

Un restaurateur et son neveu prennent une pause après l’heure de pointe du déjeuner. Le riz et les haricots constituent le repas de base quotidien des creuseurs ; une assiette coûte 500 francs congolais (environ 0,35$). Les boissons énergisantes, principalement importées de Tanzanie et d’Ouganda, sont également populaires. 15 juillet 2017

Fr:

Deux serveuses attendent les clients. Les creuseurs dépensent une partie de leurs revenus sur place. De nombreuses femmes servant des aliments et des boissons au restaurant gagnent aussi leurs vies comme travailleuses du sexe. Comme dans le cas des femmes porteuses d’eau, les restauratrices sont principalement veuves, divorcées ou célibataires. 14 juillet 2017

Fr:

Les barbiers coupent et coiffent les cheveux des clients dans un salon sur place. Les creuseurs et autres résidents du site peuvent choisir parmi une variété de coiffures ; de nombreuses options de coupe sont annoncées sur des affiches dans le salon. 15 juillet 2017

Fr:

Une multitude d’hommes au travail sur un site de traitement, où le minerai est tamisé et broyé pour en extraire l’or. Quand les sacs sont livrés par les porteurs, le processus d’extraction de l’or du minerai commence. L’extraction est effectuée par des membres de l’équipe de puits, des transformateurs spécialisés ou des creuseurs individuels traitant leurs propres sacs, qu’ils avaient reçus en paiement partiel ou intégral pour leur travail. D’abord, le minerai est mélangé à de l’eau dans les bassins en plastique pour éliminer le schiste et la mudstone. 15 juillet 2017

Fr:

Un homme s’agenouille devant une dalle de roche en écrasant du minerai d’or avec une meule. Ensuite, le minerai est manuellement broyé entre deux roches pour libérer l’or. C’est un processus lent et ardu ; un bassin en plastique peut prendre plusieurs heures à traiter. A l’arrière-plan, on voit des porteurs d’eau et des porteurs de sacs qui montent et descendent la colline de la mine. 14 juillet 2017

Fr:

Le minerai d’or est traité manuellement avec une meule sur une grande dalle de roche. 13 juillet 2017

Fr:

Un homme tamise le minerai pour trouver l’or. Une fois que le minerai a été suffisamment broyé, il est remis dans un bassin en plastique et mélangé à de l’eau. Le mercure est souvent ajouté à ce stade. Cet élément forme un composé avec l’or et, en raison de sa densité supérieure, coule au fond du bassin. Le minerai restant est rassemblé dans de grandes fosses d’eau dont les parois sont formées par des sacs de sable, et sera acheté des gérants de puits pour un traitement ultérieur par des équipes de spécialistes. 13 juillet 2017

Fr:

Un homme déverse du minerai dans une rampe de lavage (sluice). Le minerai fin acheté par les équipes spécialisées est mélangé à de l’eau et versé dans les sluices. Encore une fois, en raison de leur densité élevée, les sédiments d’or restants adhèrent à des couvertures mises dans le sluice, tandis que les excès s’écoulent en aval. Les sédiments sont ensuite rassemblés et tamisés dans un bassin en plastique à l’aide de mercure, comme auparavant. 12 juillet 2017

Fr:

Un homme se tient à l’extérieur d’une cabane tout en surveillant un site de traitement où deux écluses coulent côte à côte sur la colline. 12 juillet 2017

Fr:

Un négociant local évalue ce qu’il a à offrir pour l’or qu’un client lui a apporté. Le composé d’or et de mercure observé dans l’assiette en plastique est d’un gris métallique terne à ce stade du processus de traitement. Beaucoup de creuseurs cherchent à vendre ces petites quantités d’or – comme celle photographiée ici – à des négociants sur place. 14 juillet 2017

Fr:

Après une transaction, un négociant sur place détient l’or qu’il vient d’acheter, enveloppé dans du papier d’aluminium, tandis qu’un creuseur compte l’argent qu’il a reçu pour son travail. Une grande partie de l’or est vendue en quantités tellement réduites, inférieures à un gramme, qu’il n’est pas pesé au point de vente. Les creuseurs comme les négociants connaissent cette pratique sous le nom de « loterie », et les négociants négocieront un prix basé uniquement sur une évaluation visuelle. Ces transactions de « loterie » varient généralement entre deux et dix dollars. 14 juillet 2017

Fr:

En attendant les clients, les négociants sur place écoutent de la musique sur une petite radio portable. Les négociants locaux – connus sous le nom des « petits négociants » – se distinguent facilement des creuseurs par leurs chapeaux de cow-boy bruns et leurs porte-documents noirs. Ils peuvent échanger jusqu’à 100 g d’or par mois, réalisant ainsi des bénéfices mensuels compris entre 100 et 400$. 13 juillet 2017

Fr:

Deux négociants envisagent un achat d’or. La plupart des négociants travaillent dans le secteur minier depuis des années. Ils commencent comme creuseurs, porteurs ou laveurs et économisent petit à petit l’argent pour se lancer dans la vie moins dangereuse d’un négociant en or. De nombreux travailleurs de la mine travaillent dans l’espoir de suivre un tel chemin. 13 juillet 2017

Fr:

L’or est chauffé hors site sur un poêle à charbon à l’aide d’un ventilateur afin d’élever la température à environ 500°C. De la sorte, s’évaporeront le mercure et d’autres impuretés. Les gérants de puits accumulent de plus grandes quantités d’or que les autres travailleurs. En conséquence, ils vendront souvent de l’or à des maisons de négoce telles que celle-ci située toute proche de la mine, où l’on achète en vrac tout en offrant un meilleur prix au vendeur. 14 juillet 2017

Fr:

Un négociant hors site pèse l’or à l’aide de vieilles pièces de monnaie zaïroises et de cure-dents ; chacune de ces pièces représente un poids spécifique. Une fois l’or chauffé, il est pesé sur une balance devant le vendeur. Le prix d’achat est ensuite déterminé selon un calcul basé sur le London Gold Fixing. Des accords de crédit précédents et la grandeur de la quantité peuvent également influer sur le prix. 14 juillet 2017

Fr:

Un négociant vérifie la qualité du produit, après avoir chauffé l’or afin d’éliminer les impuretés. 14 juillet 2017

Fr:

Un bus privé, chargé de marchandises, s’arrête, suivi de près par un policier et un « receveur ». Beaucoup des petits négociants sont préfinancés par des négociants plus importants installés dans la capitale provinciale, Bukavu. Une fois par semaine environ, ils font ce voyage par un chemin cahoteux et montagneux, pour vendre leur or en ville, puis pour retourner sur le site de la mine. 22 juillet 2017

Fr:

Un négociant basé à Bukavu verse de l’acide nitrique dans un bol en métal contenant environ 23 g d’or. Une fois arrivé à Bukavu, l’or est vendu à un « grand négociant », avec une marge bénéficiaire de quelques dollars par gramme. Tout comme les petits négociants, les grands négociants ont souvent commencé dans les mines et beaucoup d’entre eux sont préfinancés par un chef auquel ils doivent vendre leur produit. 20 juillet 2017

Fr:

Un grand négociant et son assistant chauffent l’or et l’acide nitrique au-dessus d’un fourneau pour le débarrasser de toutes les impuretés qui restent. Les grands négociants acceptent des quantités d’or bien plus importantes que les petits négociants ; ils échangent souvent plusieurs kilogrammes d’or en une semaine. Leurs marges bénéficiaires sont inférieures à celles des petits négociants, mais ils négocient en plus gros volume, ce qui leur assure un revenu beaucoup plus élevé. D’un négociant à l’autre, cela varie beaucoup, allant de quelques milliers à des dizaines de milliers de dollars de bénéfices par mois. 20 juillet 2017

Fr:

Après chauffage, l’or est pesé sur une balance électrique. À ce stade, l’or a atteint une pureté comprise entre 92 et 98%, selon son origine. 20 juillet 2017

Fr:

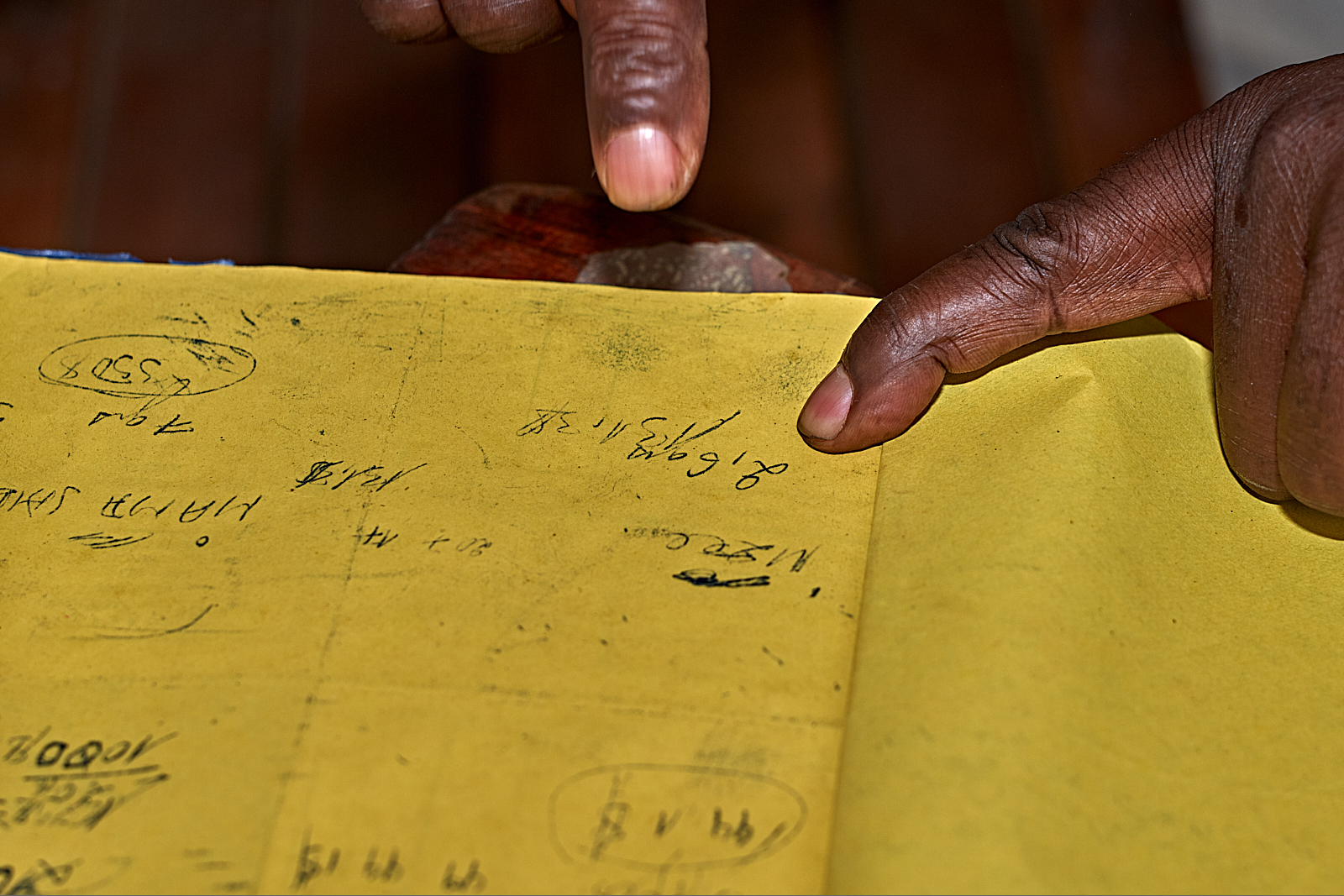

Un grand négociant désigne un achat récent dans son livre. Les grands négociants tiennent généralement des registres minutieux de leurs achats et de leurs ventes, au cas où il y aurait un désaccord. Il indique ici un achat de 2,6 g pour 131,30 $, effectué plus tôt dans la journée. 20 juillet 2017

Fr:

À l’aide d’une torche à gaz et d’une pince, un bijoutier applique de la chaleur à quelques grammes d’or placés sur un bloc de bois, afin de préparer une bague pour un client. Il y a environ une douzaine de bijoutiers locaux à Bukavu. Leur plus grande affaire est dans les alliances. Pendant la haute saison des mariages, en juin et juillet, ce bijoutier reçoit environ dix commandes de bagues par semaine. Les bijoutiers fabriquent également des colliers, des bracelets et des boucles d’oreilles. 21 juillet 2017

Fr:

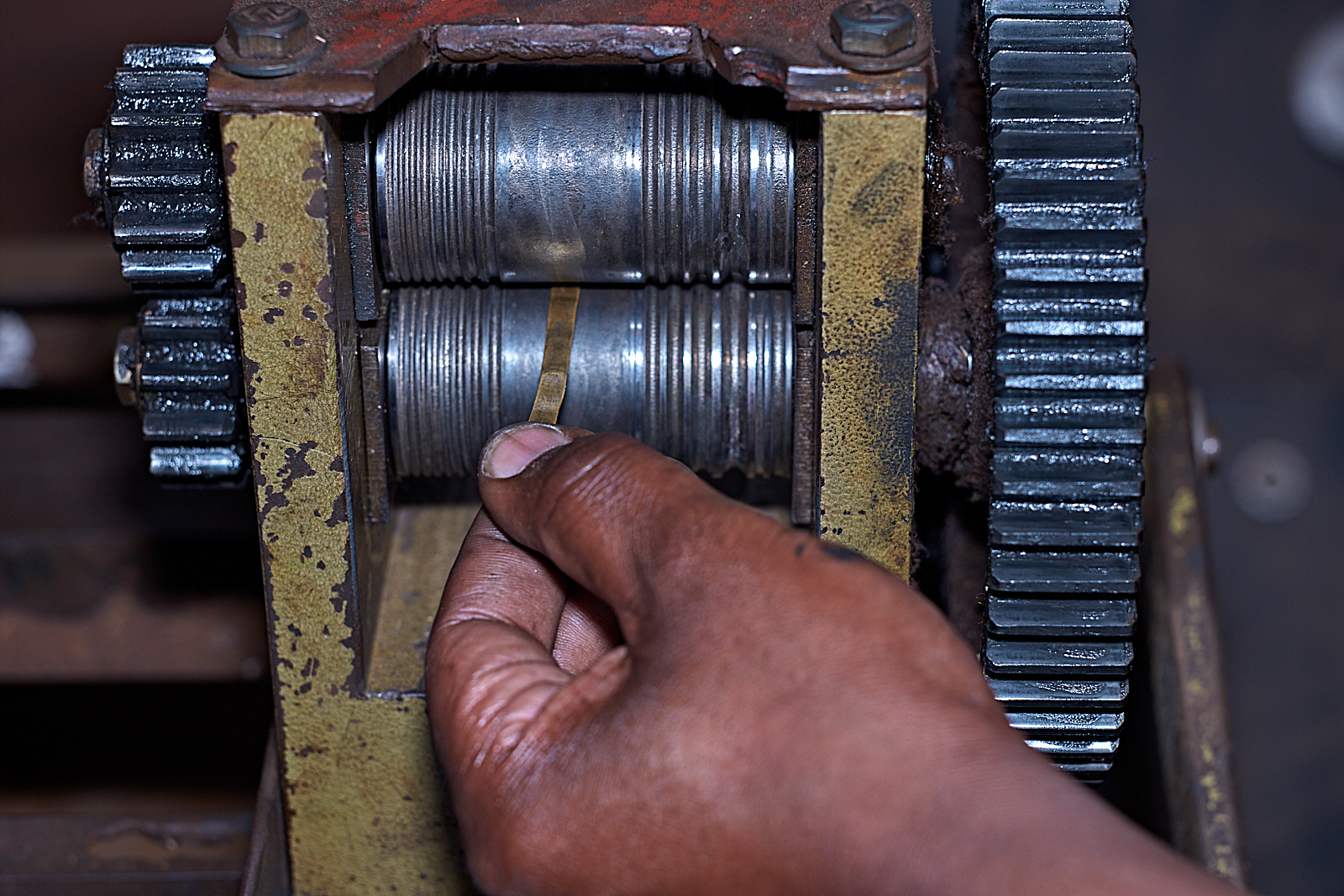

Après chauffage, l’or est aplati et étiré à l’aide d’un laminoir fabriqué localement à Bukavu. Les clients peuvent apporter leur propre or ou utiliser celui que les bijoutiers ont en stock. Les bijoutiers peuvent fabriquer une bague à partir d’un gramme d’or. 21 juillet 2017

Fr:

Le bijoutier enroule l’or chauffé et fraisé autour d’un mandrin pour que la bague convienne au doigt du client. Les deux extrémités de l’anneau sont ensuite chauffées avec une torche à gaz et assemblées à l’aide d’une petite partie d’or qui avait été retirée et conservée à cet effet lors du chauffage initial. 21 juillet 2017

Fr:

Le bijoutier commence le processus de polissage de la surface intérieure de la bague à l’aide d’un morceau de papier émeri grossier enroulé autour d’une fine tige de métal. 21 juillet 2017

Fr:

La bague finie est pesée sur une balance électronique. Ce bijoutier demande 5 $ par gramme pour son travail. Combiné au coût de l’or, ce joyau coûte au client 148,70 $. 21 juillet 2017

Fr:

La cliente porte la nouvelle bague à son doigt. 21 juillet 2017

Fr:

Dans une fonderie à Bukavu, l’or est chauffé à haute température dans un four cylindrique importé d’Italie. Les grands négociants de Bukavu cherchent à vendre en vrac aux fonderies de la ville ou à passer en contrebande leurs produits à des “maîtres-négociants” des pays voisins, afin d’éviter les taxes à l’exportation. 21 juillet 2017

Fr:

Une fois fondu, l’or est coulé dans une lingotière. Après avoir retiré du four le creuset chauffé au rouge, un ouvrier de la fonderie verse l’or dans une lingotière en graphite pour le couler. À l’intérieur du four, l’or atteint des températures de 1.500°C. Il faut environ 20 minutes pour faire fondre plusieurs kilogrammes d’or. 21 juillet 2017

Fr:

L’or refroidit rapidement à l’intérieur d’une lingotière. Il faut environ 30 secondes à l’or pour se solidifier, une fois qu’il a été sorti du four et versé dans un moule. 21 juillet 2017

Fr:

Un lingot d’or fraîchement coulé est déposé par un ouvrier sur la surface de travail ; la lingotière reste très chaude. Environ sept kilogrammes d’or ont été coulés par la fonderie lors de cette combustion, ce qui suggère un profit, après dépenses, de 10.000 $ à 15.000 $ pour la fonderie. 21 juillet 2017

Fr:

À l’aide d’une brosse métallique et d’eau savonneuse, un ouvrier de la fonderie nettoie un lingot d’or pour éliminer les résidus laissés par le moule en graphite. 21 juillet 2017

Fr:

La composition chimique du lingot d’or est vérifiée à l’aide d’un instrument de contrôle de la pureté de l’or, fabriqué aux États-Unis. Ici, la lecture révèle que le lingot est composé de 96,41% d’or et de 3,14% d’argent, soit 23,14 carats. La plupart des lingots produits à Bukavu sont passés en contrebande vers les raffineries de Dubaï aux Émirats arabes unis. Celles-ci sont équipées de la technologie nécessaire pour raffiner l’or à 99,5%, soit la pureté minimale requise pour le commerce international des lingots d’or. 21 juillet 2017

Fr:

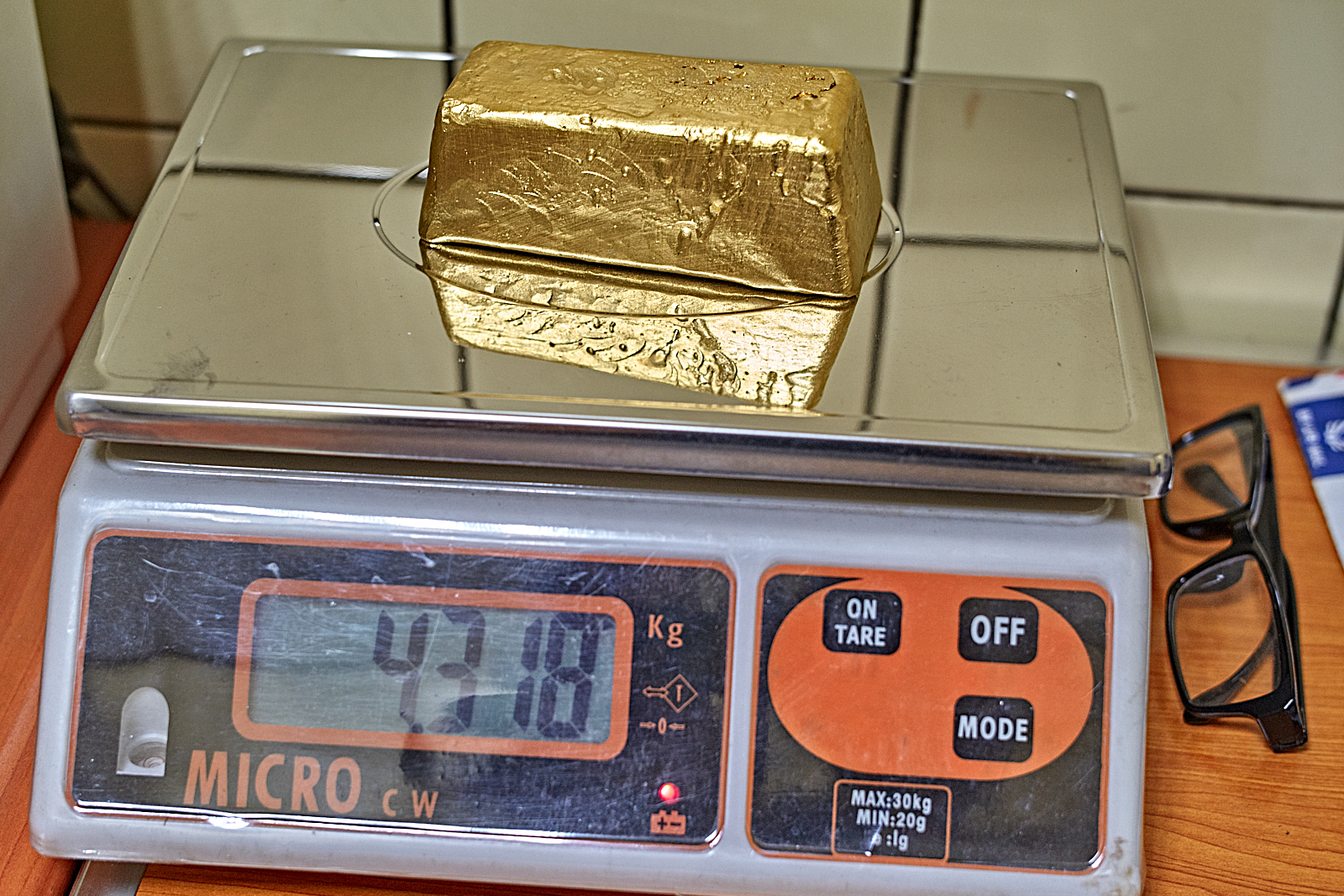

Un lingot d’or est pesé sur une balance électronique. Avec un contenu en or de 4,163 kg (ou 133,8 onces troy), ce lingot a un prix de marché de 167.056 $, au London Gold Fixing, le jour de sa production. IPIS estime la production aurifère annuelle à 11,6 tonnes pour les sites visités par ses chercheurs dans l’Est du Congo entre 2013 et 2015. Cela équivaut à environ 450 millions de dollars aux prix actuels. En 2015, les exportations officielles d’or artisanal pour la RDC ont été enregistrées à seulement 254 kg. 21 juillet 2017

Receive updates about our films and articles by subscribing to our newsletter: